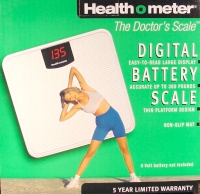

Digital Test Stand

Remember 2001? I can recall bits and pieces.

| Flab-O-Meter Digital Test Stand Remember 2001? I can recall bits and pieces. |

|

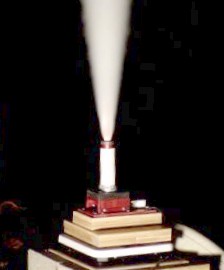

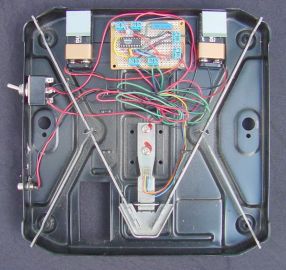

"DigitalThis describes what I saw under the hood pretty well.

- Weight is evenly distributed through the brackets and levers

- Long levers are connected to a beam

- A stain gauge is bonded on the beam

- Deflection of beam causes the change in resistance

- Output signal is translated to weight reading on LED display"

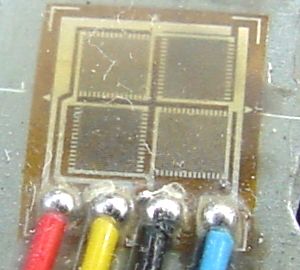

Red: Excitation +I drilled a hole for a power-on LED but didn't use it.

Black: Excitation -

Blue: Signal +

Yellow: Signal -