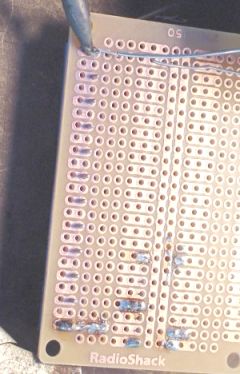

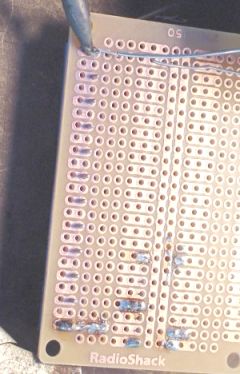

Note that solder can be "bridged" between adjacent spots to connect them electrically.

|  |  |

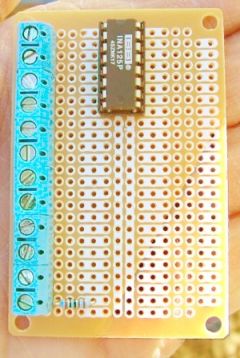

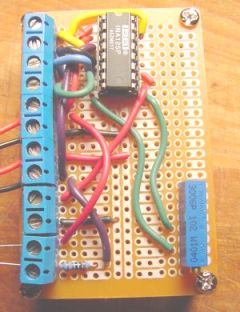

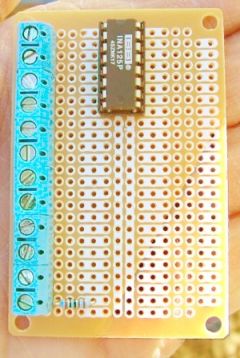

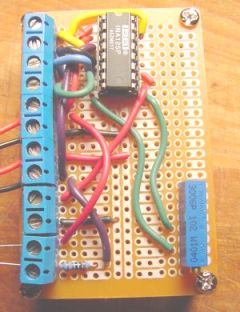

| Here is one with a few parts on it. | The backside, showing copper traces. Note that solder can be "bridged" between adjacent spots to connect them electrically. | Fully populated board. Note wires used to run current from one spot to the other. Wires can be run on the solder-side too, but I prefer to put all my wires on top where I can see them all at once. |